Spiroflow Automation Solutions has more than 17 years of experience offering automated solutions for the prepared foods, confections/candy, dairy, and frozen food industries. Our engineers understand the procedure for entering a food processing and manufacturing facility as well as working within that environment. Our experience includes CIP systems, cooking and cooling systems, HTST and UHT systems, batching and blending, tray fillers, 21 CFR part 11 complaint reporting systems and SCADA systems.

With this depth of expertise, we know what you need to meet the regulations of your industry.

Ready To Improve Efficiency?

PREPARED FOODS

Spiroflow Automation Solutions’ controls monitor ingredients as they’re mixed which includes monitoring their temperature as well as how they’re moved. We understand the importance of refrigeration as well. Our controls monitor the cooking and cooling process, CIP systems, batching and blending. If your process calls for filling or variable frequency drive servo systems, we have you covered too.

If your plant has old motor controls, our team can help you retrofit and upgrade your processes. We can take old gear and replace it with new equipment. We’ve observed more and more prepared food plants moving in this direction.

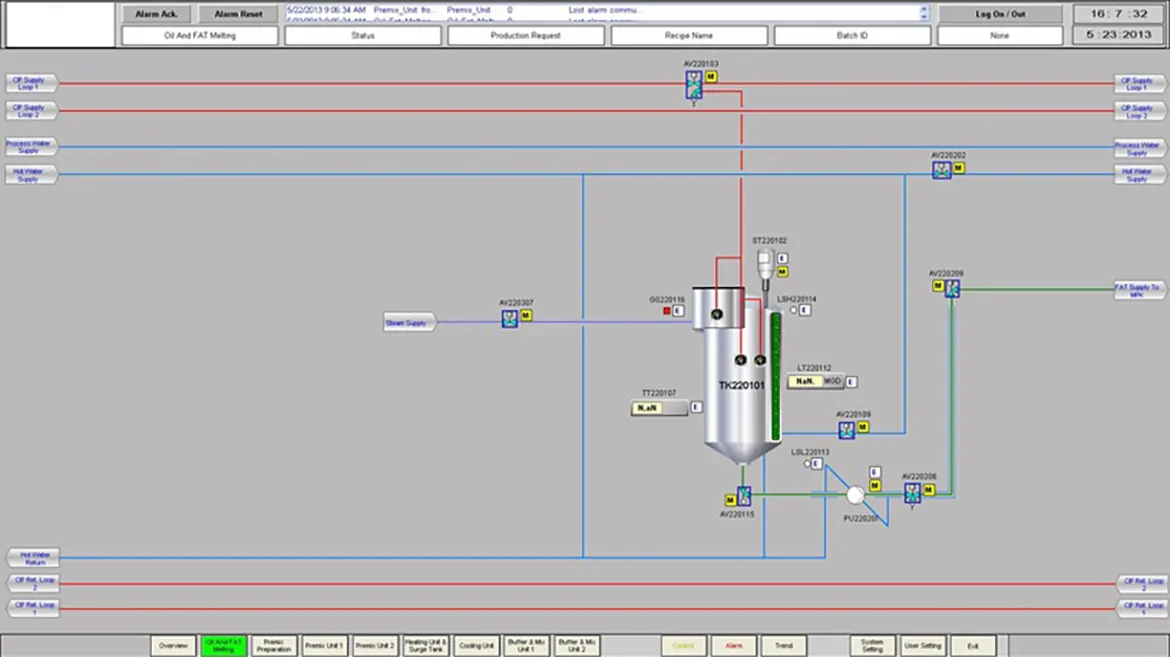

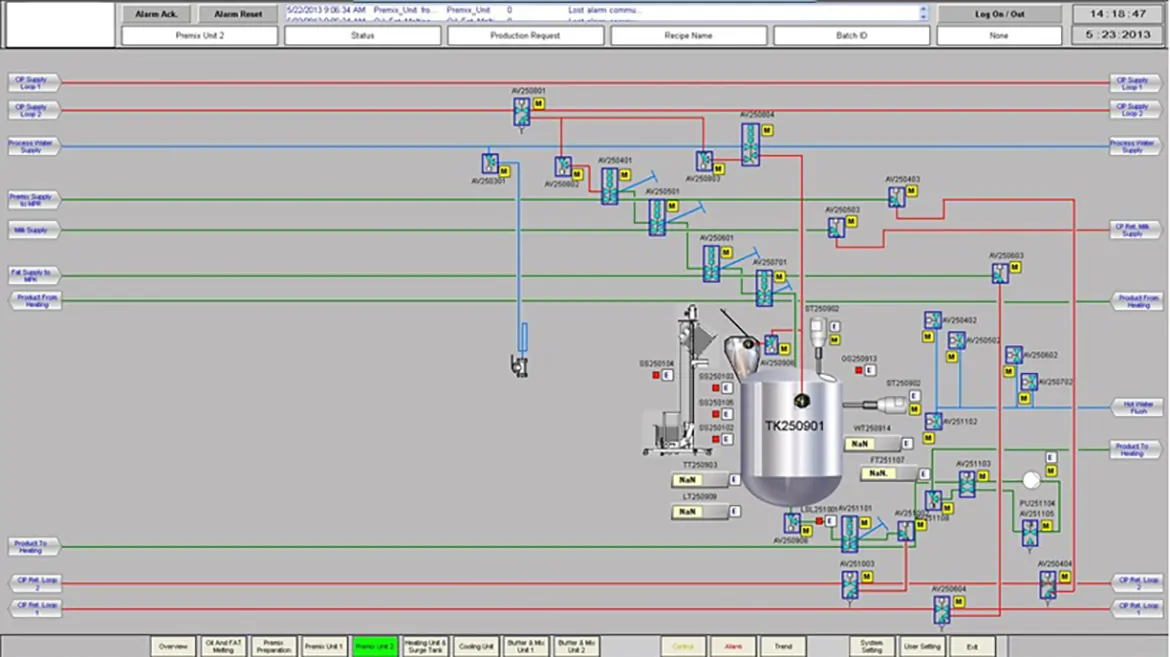

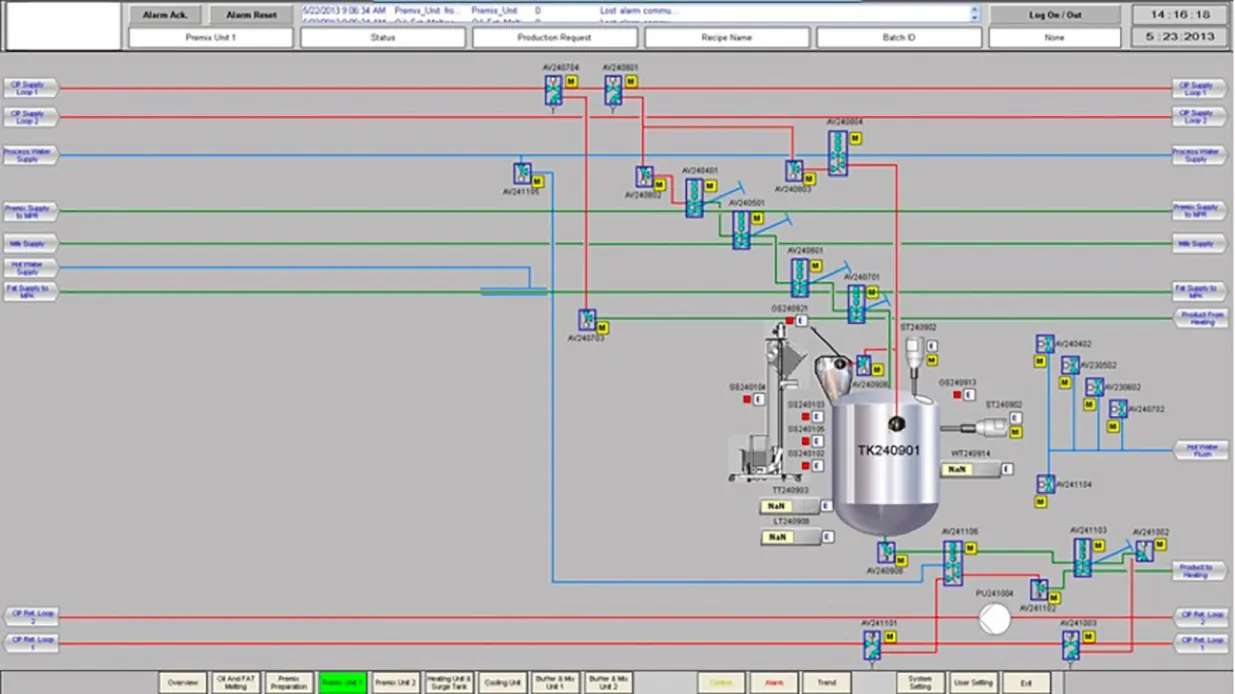

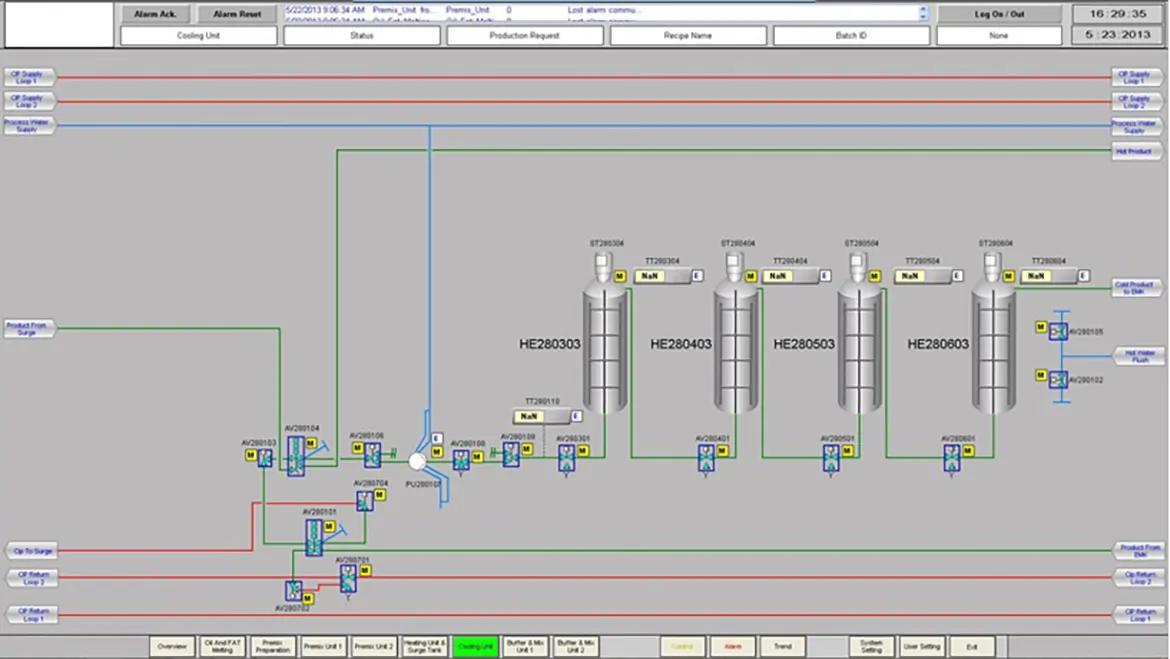

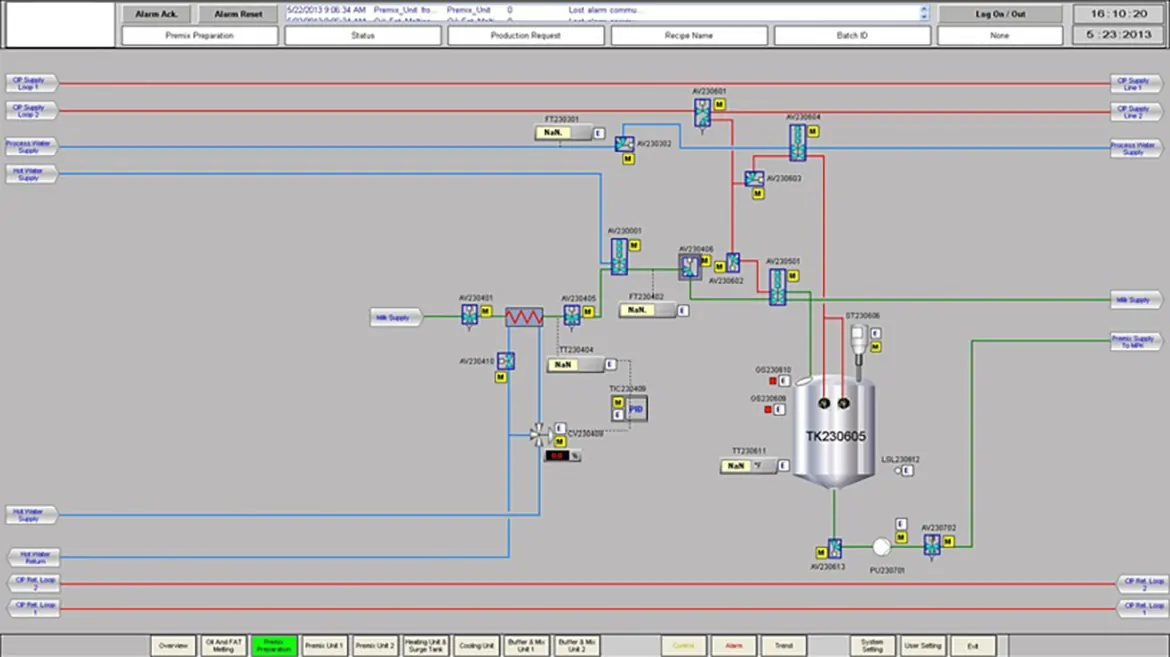

Here are examples of control systems for manufacturing sauces using Wonderware InBatch for a frozen prepared food plant.

Dairy

We understand that when raw milk arrives at your plant that it needs to be pasteurized, separated, homogenized, and then re-blended. Spiroflow Automation Solutions’ controls help those processes every step of the way.

Automation will ensure a quality product every single time. Our controls will monitor the blending, batching and clean-in-place systems.

Our integration capabilities also extend to the high-temperature short time (HTST) controls form of pasteurization, homogenizers, ingredient data collection, the control of pumps, valves, and refrigeration controls.

Beverages

Our team has batch mixing experience in the juice and coffee industries. We are a Rockwell Automation Recognized System Integrator as well as a Wonderware Registered System Integrator. Spiroflow Automation’s controls use batch software to prepare the mixes by pulling ingredients from various sources, monitoring the mixing, and keeping the product moving.

Candy & Confections

Our team has expertise in raw material and finished product handling in candy and confections plants. Our controls monitor materials from the oven through to the packaging line.

Do you have safety features already in place? Spiroflow Automation’s controls interface with metal detectors, x-rays, and checkweighers. Our controls interface with these components via Ethernet. As a result, we can provide status reports on your product as it moves through your process.

Ready to improve efficiency?

Our team of seasoned engineers is on stand-by, ready to discuss your project. Get in touch for a free consultation.

Talk to an Expert